Introduction

Inventory management has undergone many changes in recent decades. It has progressed from paper-based counts and manual ledgers to barcode / RFID tracking and centralized ERP systems. Technologies significantly increased efficiency and visibility; however, they were limited to static rules and batch reporting.

AI today injects real-time intelligence, automating replenishment, detecting anomalies, and continuously optimising stock levels without human intervention.

As supply chains have grown more complicated, energised by e-commerce, omnichannel fulfilment, and just-in-time strategies, the COVID-19 disruptions exposed the shortcomings of traditional processes. After the pandemic, companies were eager to implement AI-powered control towers, machine-vision inspections, and predictive analytics to remain flexible in an unstable environment.

Currently, AI plays a significant role in business continuity and is no longer an experimental add-on. Intelligent automation from SKU-level demand forecasting to dynamic safety-stock adjustments not only guarantees cash flow, reduces stockout, but also enables the meeting of customer demand even if some unexpected events occur.

Types of AI Technologies Used in Inventory Management Machine Learning (ML)

Forecasts aim to avoid stockouts and excessive stocks. It also optimises lead time prediction and dynamic reordering for the best stock levels.

Natural Language Processing (NLP)

Facilitates voice-controlled warehouse operations for picking and searching without using fingers, thus, errors. In addition, it carries out the analysis of the communication of unstructured sources such as emails for the extraction of the most important information.

Computer Vision

Enables drone or camera-based automated inventory counting, significantly enhancing audit speed and accuracy. Critical for damage assessment and quality control during goods inspection.

Internet of Things (IoT) + AI

Offers real-time asset visibility and tracking seamlessly via smart sensors on equipment and goods without the need for manual inputs. It also provides environmental monitoring for perishable goods, which goes further to send an AI-powered alert in case there is a signal of going bad.

Robotic Process Automation (RPA)

Robotic Process Automation (RPA) Simplifies repetitive, rule-based digital tasks such as report creation and data cleaning between systems. It also automates invoice reconciliation and purchase order processing.

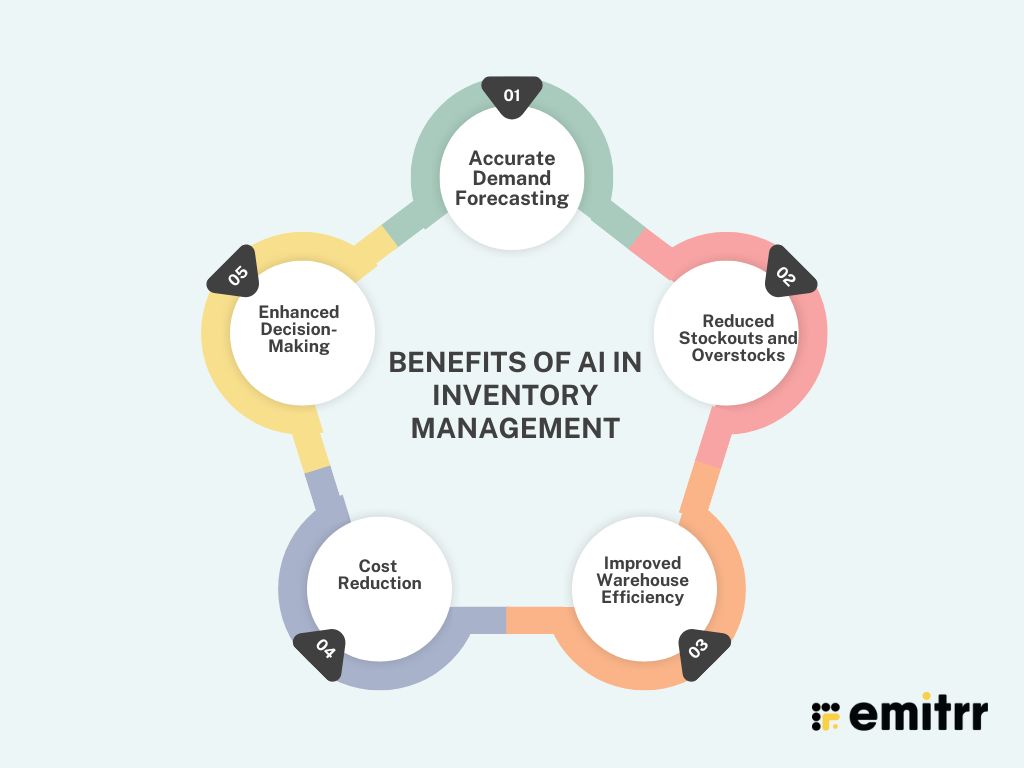

Benefits of AI in Inventory Management

Accurate Demand Forecasting

AI employs machine learning to haul data from Big Data, including historical sales, market trends, seasonality, and external factors (weather, social media sentiment). This enables AI to make super-accurate forecasts of future demand way beyond traditional methods. AI makes sure you understand exactly what customers will want and when.

Reduced Stockouts and Overstocks

When demand is estimated accurately, AI assists in establishing the best stock levels. This sets the stage for stocks (lost sales and customer dissatisfaction) and, at the same time, cost-efficient overstocks (excess holding costs, spoilage, obsolescence) resulting in a lean and efficient inventory.

Improved Warehouse Efficiency

AI is not only good at path optimisation, but it also gives direction to a human or a robot worker’s pick path. Additionally, it is possible to automate routine tasks, such as inventory counting. This can be done via computer vision. In practice, digitizing labels during counts improves accuracy by using barcode reading and text recognition approaches that reliably capture information from images. Moreover, it can develop an intelligent system that automatically assigns storage locations. This action alone makes work easier and consequently reduces labour time while speeding up the processes of fulfilling orders.

Cost Reduction

The two most important items in stock, accurate forecasting and stock level optimisation, coupled with operational efficiency, directly translate to significant cost savings. Among these savings are lower holding costs, less waste owing to obsolescence, fewer expedited shipping fees, and reduced labour expenses owing to automation.

Enhanced Decision-Making

Decision-making gets a boost from AI as it brings real-time insights and data-driven recommendations, thus bypassing the need for intuition. It also helps managers make decisions by signalling errors, detecting trends, and running various scenarios in simulations. Thus, managers become decision-makers with actionable intelligence at hand, allowing them to make faster and better choices concerning purchasing, pricing, or the supply chain.

Use Cases of AI in Inventory Management

a. AI Inventory Forecasting

Utilises machine-learning models to go through historical sales data, seasonality, and external data (promotions, weather, holidays) for SKU-level demand predictions, allowing you to reduce stockouts and overstocks by up to 50%.

Example: Blue Yonder’s Luminat Demand Forecasting is an AI-powered solution that can improve retail forecast accuracy by 30%, thus enabling merchandisers to optimise replenishment and markdown plans.

b. Smart Replenishment Systems

This can dynamically adjust reorder points and safety-stock buffers by taking into account, in real time, sales velocity, supplier performance, and lead-time variability, which will result in a reduction of carrying costs by ~20%.

Example:

The replenishment system of Zara will automatically refill the top-selling items in the flagship stores the top-selling items within hours after a sale.

Emitrr’s AI platform connects to your ERP/WMS, and it will send SMS/email PO alerts and supplier follow-ups in addition to the automatic response of the participants, thus reducing lead-time variance by 20%.

c. Warehouse Robotics & AI

This merges autonomous mobile robots (AMRs) with AI-run pick-path optimisation to significantly reduce travel time, whereas the robotic arms take care of case/carton tasks, thus lifting throughput by 2–3× and freeing staff for value-added work.

Example: Amazon’s Kiva robots, powered by AWS Robotics, reduced order-cycle times by 20% and tripled pick rates in high-volume fulfilment centres.

d. Computer Vision for Inventory Auditing

Fixed cameras, drones, or handheld AI-driven scanners are utilized to do continuous cycle counts, report mis-picks, and flag damaged goods in real time with >99% accuracy thus, no manual spot checks are necessary.

Example: Walmart’s Bossa Nova shelf-scanning robots reach 100,000 SKUs per hour and report out-of-stocks and planogram errors automatically.

e. AI in Warehouse Management Systems (WMS)

A WMS that is empowered with AI modules allows for dynamic slotting, labour allocation, and “what-if” scenario simulations, thus providing 15–25% improvement in put-away and picking efficiency.

Example: DHL’s implementation of Manhattan Associates WMS that has AI in it reduced order-processing times by 18%, and the dock-to-stock cycle was faster by 22%.

By integrating these AI use cases along with Emitrr’s real-time communication layer, you can transform static warehouses into self-optimising and resilient fulfilment networks.

Challenges & Disadvantages of AI in Inventory and Supply Chain

High Implementation Costs

Deploying AI for inventory involves huge expenses, which are spent on software which is specialised, high-performance software of high-performance performance, and integration that is complex. These huge initial and current costs are a major stumbling block for small businesses, especially.

Data Dependency

The success of AI relies entirely on the quantity and quality of data being supplied. The quality of data is essential because only good and clean data can help AI algorithms learn and thus make the right decisions. The error in data will lead to wrong prediction, and hence, the decision will be wrong too, thus the AI’s value will be lost.

Skills Gap

A great shortage of individuals with specific skills in areas like data science, machine learning, and AI ethics is the major problem. The organisations are in a situation where the staff that is skilled and can be hired or trained are needed for the development, implementation, and maintenance of the complex AI solutions, but they usually are not able to find the workforce.

Over-Automation Risks

Too much trust in AI can lead to the loss of the role of human supervision. AI may still not be able to handle unpredictable interruptions or new situations that are outside its training data; therefore, it might be the case if human validation is not used that the errors happen or the machine is not flexible.

Compliance and Data Privacy

In the course of processing considerable supply chain data, there are potential significant concerns about data privacy, security, and regulatory compliance that need to be considered. Ethical assurance of data use and protection from cybercrimes makes it difficult for the process to be smooth and uninterrupted.

Traditional vs. AI-Based Inventory Management

| Traditional Inventory | AI-Based Inventory | Benefits of AI |

| Manual stock counts | Automated real-time tracking (via RFID & sensors) | Reduced labour costs, improved accuracy, and minimised stockouts/overstocks |

| Reactive ordering | Predictive replenishment based on demand forecasting | Optimised inventory levels, reduced holding costs, improved customer satisfaction |

| Siloed data | Unified dashboards with real-time data visibility | Improved decision-making, enhanced collaboration across functions, and faster identification of problems. |

| Human errors | ML-powered accuracy and anomaly detection | Eliminated costly errors, increased operational efficiency, and achieved greater reliability |

| Slow response to market shifts | Dynamic inventory optimisation & adaptive planning | Increased agility, improved responsiveness to customer demand, competitive advantage |

Where does AI overtake humans in Inventory Management?

Artificial Intelligence (AI) is basically changing the way inventory management is being done by taking over jobs where human limitations are seen, such as data processing capacity, speed, and complex pattern recognition. AI can process massive, diverse datasets with great precision, which allows it to multiply the human-centric methods in several critical areas many times.

1. Hyper-Accurate Demand Forecasting

Conventional demand forecasting approaches that utilise historical sales records, human intuition, and only a few variables have certain limitations. This method is not able to handle the market volatility, seasonality, and the effects of many external factors in a very subtle way. The limitations mentioned above usually result in unnecessary stock that costs too much, or if there is no stock, then sales lose the opportunity of being made.

AI’s Superiority: AI, mainly machine learning algorithms, is extremely efficient in lots of data processing. In addition to historical sales, promotional impact, macroeconomic indicators, weather, social media sentiment, etc., these algorithms incorporate real-time customer browsing behaviour. Machine learning methods such as deep neural networks and Prophet models input these data streams and produce non-linear, dynamic demand that closely reflects consumer behaviour, thereby enabling inventory to be replenished optimally.

2. Real-time Inventory Visibility & Anomaly Detection

Humans carrying out inventory tracking manually and performing routine inventories periodically are not only prone to errors but also create situations whereby the inventory state is only a snapshot and is time-lagged. Manually finding errors or abnormal patterns in a large stock of things is very tedious and inefficient.

AI’s Superiority: AI systems that are combined with RFID, IoT sensors, and computer vision technologies deliver real-time, detailed visibility into the exact location, movement, and condition of each item throughout the whole supply chain. AI algorithms are able to quickly identify anomalies, like an unexpected stock drop for a popular item, unusual movement patterns, or differences between digital records and physical counts, thus enabling the immediate implementation of corrective measures against theft, mistakes, or new supply chain problems.

3. Dynamic Inventory Optimization

It is no secret that the traditional method of human operators adjusting inventory levels, reorder points, and safety stocks across thousands of SKUs and several locations is something they can hardly manage. The problem is that the decisions are mostly based on rules that are static or broadly averaged numbers, which lack the required agility for modern supply chains.

AI’s Superiority: AI repeatedly perfects inventory settings (e.g. order quantity, reorder points, safety stock) by continuously analyzing present data on demand, lead times, supplier performance, and cost limitations. Using prescriptive analytics and reinforcement learning, AI systems provide the best stock distribution plan to warehouses thus, they not only reduce the storage, obsolescence and stockout costs, but also they keep the stock level suitable for the market changes.

4. Automated Replenishment & Order Management

Order generation manually is a work that requires much effort, a long time, and is prone to human mistakes. It creates inefficiencies due to the fact that it needs human monitoring of stock levels and supplier lead times constantly.

AI’s Superiority: Systems that are AI-enabled can initiate precise purchase orders or transfer requests without any human intervention, exactly at the point where stock levels reach the thresholds that have been dynamically adjusted. These systems take into consideration the projected demand, the existing stock, the goods that are on their way, and the lead times of the suppliers. This automation significantly cuts down on manual work, it makes the replenishment cycle faster, and it also ensures that the product will be available on time; thus, it liberates the human staff for more strategic tasks as they won’t need to do something that can be automated.

5. Superior Data Analysis & Insight Generation

Humans are, by their nature, limited in their ability to process, analyse, and find meaningful patterns in very large quantities of varied and rapidly changing data. Additionally, insights obtained from manual analysis are usually backwards-looking, which restricts proactive decision-making.

AI’s Superiority: AI’s Superiority: AI can quickly go through and analyze huge, complicated data sets, find the hidden correlations, the new trends, and the unexpected inefficiencies that are not visible to human analysts. It gives truth to data that businesses can use to make more intelligent, data-driven decisions about pricing, promotional strategies, product assortment, and overall supply chain resilience, the most important being that they can often forecast the future instead of just reacting to the past.

In sum, human intervention and strategic decision-making are still of utmost importance; however, AI’s unrivalled talents of data absorbing, prediction precision, never-ending optimisation, real-time execution, and steady output allow it to radically change and improve inventory management to a degree that would have been unimaginable by human effort alone.

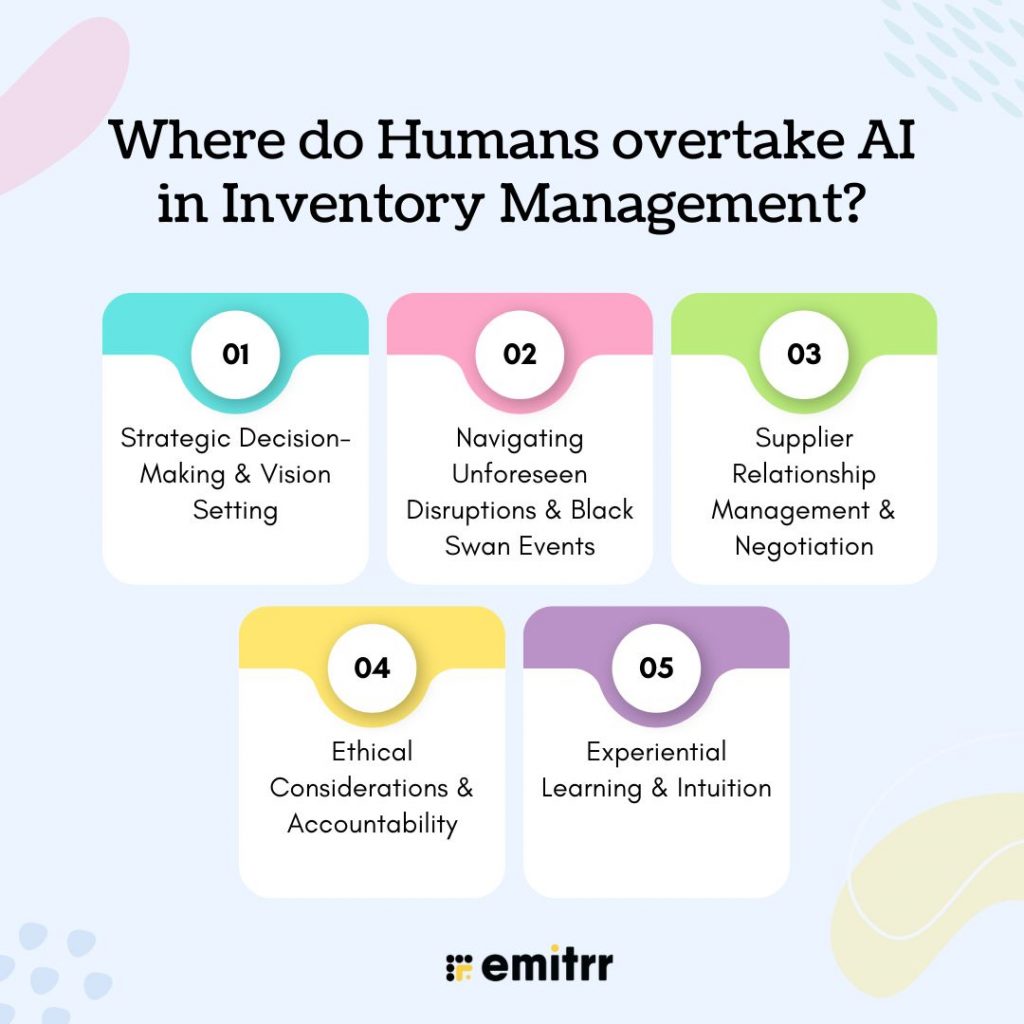

Where do Humans overtake AI in Inventory Management?

While AI offers numerous advantages in inventory optimisation, there are still crucial areas where human intellect, adaptability, and sound judgment are invaluable and often surpass AI in effectiveness.

1. Strategic Decision-Making & Vision Setting

AI can make the most of the processes based on a certain set of goals, but it is not the one that establishes the overall business strategy or vision. This technology cannot generate ideas for growth in the long run, plan strategies for entering the market, or change the basic business model.

Human Advantage: Humans decide the main objectives of inventory management and ensure that it is compatible with the overall company goals, like going after new markets, sustainable development projects, or new product category launches. They are the ones who choose products to invest in, decide the markets that are more important, and figure out how to balance inventory costs against strategic growth, brand image, and competitive positioning. AI supports estimation and optimisation, but the strategic “why” and “what next” come from human leadership.

2. Navigating Unforeseen Disruptions & Black Swan Events

Artificial intelligence models get trained using old data, which enables them to be very good at guessing results based on previous examples. But they have difficulties with really new situations, so-called black swan events – completely unforeseeable events and for which there is no historical record (e.g., a sudden global pandemic, an unprecedented natural disaster, or a unique geopolitical crisis).

Human Advantage: Humans are equipped with the ability for adaptive intelligence and creative problem-solving when facing completely new or highly ambiguous situations, none of which AI can do. The assignment includes changing supply chains completely or, in the case of a scenario that has never happened before, finding out alternative sources that will be used instead.

3. Supplier Relationship Management & Negotiation

Even though AI can look into supplier performance data, it does not have the emotional intelligence, understanding, and subtle communication skills needed for building and retaining trustful, collaborative relationships.

Human Advantage: Human nature has a significant impact on the performance of supplier relationship management beyond the mere collection of data. Individuals are those who create trust, negotiate intricate contracts, solve problems amicably, build up long-term partnerships, and collaborate on innovation. They can read subtle signs, change negotiation strategies, and make decisions based on the conduct of suppliers and the importance of the case, which is still very necessary for getting favourable terms and for supply chain resilience during the emergency.

4. Ethical Considerations & Accountability

Artificial intelligence is not perfect because it depends on algorithms while the data used can contain biased segments. In such a case, if the AI system makes a wrong or unethical decision and it is not clear who is responsible for the mistake, it can be difficult to assign the liability.

Human Advantage: People are the ones who set ethical principles, ensure that justice is realised, and solve problems arising from the possible presence of errors in AI systems. They ensure that there is human supervision and accountability for the decisions made by AI. In the end, it is humans who take over the ethical and legal responsibility for the results of inventory strategies so that they can check, confirm, and, if necessary, interrupt AI recommendations on the basis of moral principles or the impact on society.

5. Experiential Learning & Intuition

The way AI learns is by getting data and patterns that are explicitly defined. Nevertheless, human specialists go through a process of “gut feelings” or intuition that is based on numerous diverse qualitative experiences and tacit knowledge, over the years, which are difficult to convert into algorithms.

Human Advantage: Experienced inventory managers have great experiential knowledge, and their intuition makes it possible for them to come to quick, effective decisions even in cases when they have very little data or it is unclear. They can observe how unrelated elements are interconnected, allowing them to predict market changes based on faint signals or identify opportunities that may not be evident in quantitative data alone.. This “feeling” for the market perfectly goes along with the AI’s data-driven insights.

In conclusion, while AI excels in the computational and data-driven aspects of inventory management, humans are irreplaceable when it comes to strategic vision, adaptable problem-solving in novel situations, nuanced relationship management, ethical governance, and the invaluable application of experience-based intuition. The most effective inventory management leverages the combined strengths of both human intelligence and artificial intelligence to create a synergistic partnership.

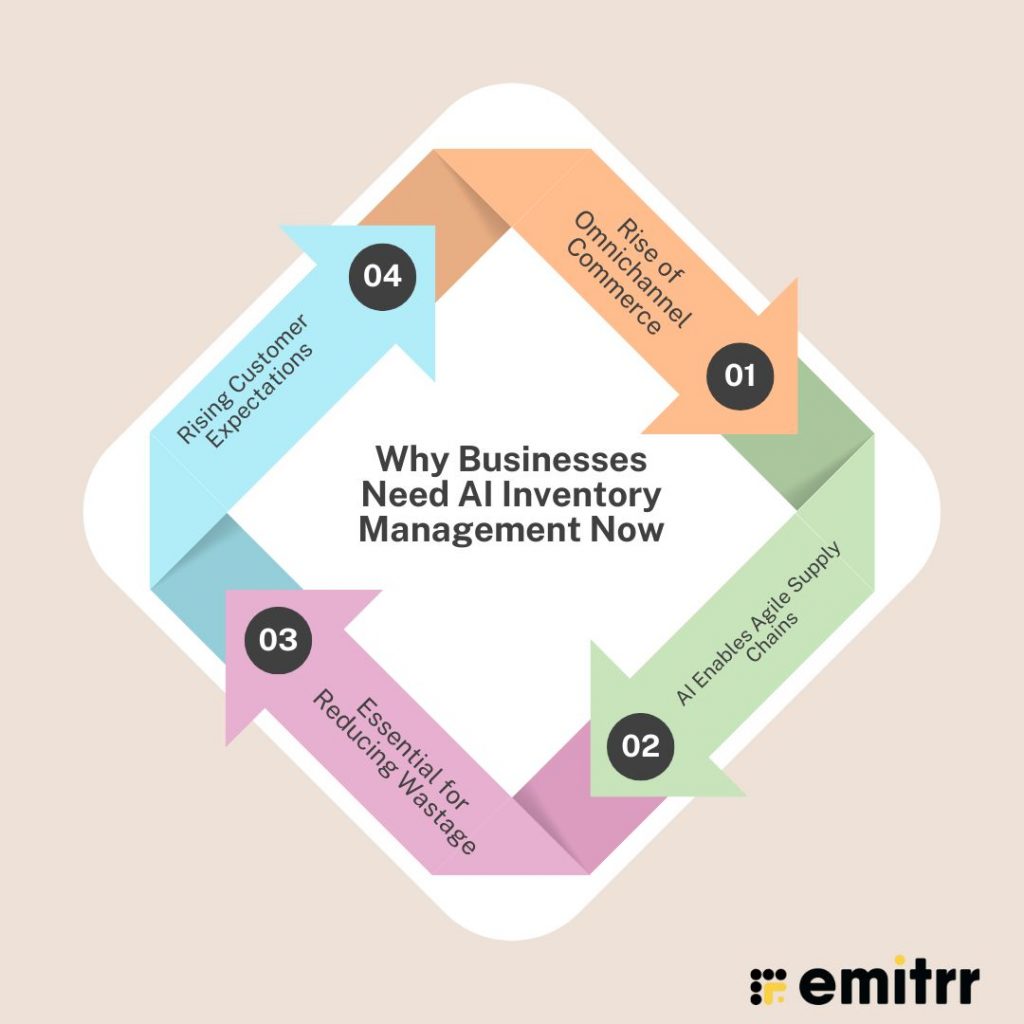

Why Businesses Need AI Inventory Management Now

In today’s rapid, over-connected marketplace, conventional inventory systems are not able to keep up with the needs of modern commerce. Here are the reasons that an AI-driven inventory management is no longer optional; it is essential:

1. Rise of Omnichannel Commerce

Since customers buy goods through various channels such as physical stores, mobile apps, marketplaces, and social platforms, businesses need real-time inventory that is visible at all channels. AI is a powerful tool that can help keep stock levels consistent, avoid overselling, and guarantee smooth fulfilment no matter where the order comes from.

2. AI Enables Agile Supply Chains

By constantly evaluating supplier’s performance, lead times, and demand changes, the AI-based system can decide procurement and distribution on the fly. This quickness gives businesses the power to react more swiftly to unexpected situations, stay on top of inventory levels, and still meet service customer requirements even in changing conditions.

3. Essential for Reducing Wastage

Overstocking not only ties up your money but also leads to situations where you have to throw away the goods or they become obsolete, bunches of things, especially in the case of food, fashion, and electronics. AI does so using predictive analytics to fine-tune reorder points and safety stock, thus greatly helping in reducing waste without forgetting the availability.

4. Rising Customer Expectations

Modern customers demand quick, precise, and tailored services at all times. AI allows for better demand planning, speedier order execution, and timely notifications, which is the case for making sure the right goods are at the right place at the correct time.

Why Emitrr is the Ideal AI Platform for Inventory Management

Emitrr provides a comprehensive set of highly specialized AI-driven tools that are made just for increasing the efficiency and communication in inventory operations. Utilising the ideas of AI in Operations Management and AI in Business Management, Emitrr improves the efficiency of the inventory workflows by:

AI Communication Assistant: This is a great way to save time because it automates the routine work for all inventory staff, suppliers, and stakeholders. It also instantaneously gives the right data, like stock levels or order statuses.

Multilingual Support: This makes communication with people from all over the world easier and trouble-free. It also cuts down on language barriers in the case of international interactions.

Seamless Integration: This option allows users to add the AI capabilities directly into the existing inventory systems, such as ERP and WMS, thereby achieving a single platform for all those processes that are the most efficient ones.

24/7 Availability: This feature guarantees the continual supervision and also helps in getting immediate answers to the critical inventory events, thus facilitating the improvement of the responsiveness and reliability.

Emitrr enables the inventory managers to direct their time and energy into more strategic tasks rather than execution by automating the routine communication, which in turn results in the improvement of the overall operational quality and efficiency.

Announcement: Deployment Update: AI Text Enhancement Features Available Now!

Emitrr’s AI-driven text enhancement features are now available to you.

- Help Me Write: Based on prompts, this creates whole pieces of text (e.g., supplier replies, stock announcements).

- Enhance:

- Make it Crisp: Shortens and sharpens messages for clarity.

- Make it Empathetic: Adds a professional yet warm tone for sensitive communications.

- Suggest a Reply: Provides auto-replies based on incoming messages (e.g., confirming supplier emails, responding to stock inquiries).

Note: The features mentioned are only available in Emitrr’s Professional Plans.

Watch this quick video to see how Emitrr’s AI agent Sarah makes texting effortless –

Addressing Industry Challenges

Emitrr is the one who solves the biggest problems in inventory management, such as: The high demand for quick responses, the need to minimize operational costs, and the optimal interaction within the supply chain, present complex challenges.

- Lowering Operational Load: Automates repetitive tasks, thus shortening the number of manual processes and the possible mistakes caused by human error in the exchange of information.

- Boosting Supply Chain Responsiveness: Gives the correct, individualised information to all the parties at the right time, thus satisfying the need for a fast and exact flow of information.

- Making Staff Efficiency Better: Enables inventory staff to concentrate on strategic tasks, resulting in increased job satisfaction and reduced burnout being less.

These solutions are not only the reasons for the improvement of the efficiency but also the causes of the work environment being more satisfying and the inventory system becoming more resilient.

Future Trends: What’s Next for AI in Inventory and Warehousing

Transformations in warehouse logistics continue in rapid and unexpected ways. Proliferating networks of hyper-connected data systems have led to the era of AI-induced automation. Efficiency, transparency, and resilience all take larger strides thanks to AI. Let’s explore the top five trends that are revolutionising the inventory and warehousing operations.

AI + IoT integration for zero-touch, fully autonomous inventory environments

The Internet of Things (IoT) spreads that it contributes to all around through smart sensors on racks, pallets, and shipping containers that keep streaming forever the location, temperature, and movement of the tracked things. AI engines then follow the logic of this real-time feed to:

- Without the need for manual intervention, stock levels always reflect reality as goods are received, moved, or shipped

- Recruit new orders, plugging in just what has run out at the exact moment

- Reconfigure storage space through a dynamic system that gives the most efficient pick routes and requires less time for retrieval.

Ultimately, it is like an invisible and noiseless robot operating the facility where picking and replenishing tasks can be fully automated, and human interaction is limited to handling exceptions, greatly reducing labour costs and inventory errors.

Blockchain with AI for transparent, tamper-proof inventory audits

Joining AI analytical power with a blockchain register makes an audit information system that is both clever and immutable:

- Blockchain is responsible for the security of every stock move, time stamp, and forking transaction in a decentralised, tamper-resistant record.

- AI keeps the physical counts continually updated against the chain, automatically detects faults (e.g., pallets that have disappeared, and unexpected SKU swaps), and plans the searches most profitable for a given ROI.

This convergence safeguards against fraud, streamlines compliance reporting, and accelerates root-cause investigations.

Self-healing supply chains using AI to reroute and correct stock shortages

Disruptions—be it that a truck vehicle is broken or a sudden demand spike—do not impact the fulfilment process as severely as before. AI platforms collect data from various sources, including carriers, weather services, order management systems, and social media, to:

- Spot new stock shortages or delivery delays within the blink of an eye

- Grab alternative routes, carriers, or even redistribution hubs in the nearest area automatically

- Supply ERP and WMS with the newest data, generating new pick/pack without human intervention.

Such networks, which are self-healing, can supply and satisfy customers continuously even under the most volatile conditions.

Voice-based warehouse operations through NLP and smart devices

Hands-free workflows have become very popular, especially at places that are high-velocity e-commerce hubs:

- Wearables & Headsets vocally give out the pick-list; hence, associates can work with both hands on the pallet jack or scanner.

- Voice NLP engines listen to the natural command (“What’s next bin in Aisle 4?”) and repeat the task (“Picked 12 units of SKU-1234”).

- Real-Time Feedback not only can reduce scanning errors by up to 30% but also can speed up the onboarding of new employees.

Augmented Reality + AI for guided inventory picking and audits

AR glasses—AI vision-powered—signal instructions where employees are looking:

- Mark the exact location on the shelf and the count for each SKU

- Indicate arrows on the floor to show the best picking routes.

- Use automatic barcode or QR code scanning for instant verification

FAQs

AI transformed inventory management by automating predictive demand forecasting, avoiding overstocking and stockouts. It maximises stock levels, automates reordering, and increases real-time tracking for improved accuracy. AI also maximises warehouse productivity, such as picking and packing, and significantly reduces costs.

Although some business-oriented AI technologies are expensive, most affordable AI inventory solutions are now accessible to small businesses. Solutions have plans as low as $29/month, making features such as real-time tracking and automated reordering available via AI. Scalable and affordable solutions for small and medium-sized enterprises (SMEs) are the focus.

AI does not typically displace warehouse workers completely, but it redesigns them. AI automates repetitive and labour-intensive tasks like picking, packing, and sorting, allowing human workers to focus on more complex, strategic, and problem-solving roles. It directs the workforce towards management, upkeep, and data analysis, opening up new positions in AI-based warehouse settings.

AI-based inventory data safety is a priority issue. Strong AI systems leverage sophisticated encryption (at rest and in transit), access controls (such as RBAC), and anonymisation of data to safeguard sensitive data. Ongoing monitoring and AI-driven anomaly detection also add an extra layer of security by capturing and highlighting unusual activity or potential data violations in real time, preserving data integrity and confidentiality.

AI in inventory management offers a high return on investment and is also very intricate. Such a return leads to a whole range of cost savings that are quantifiable and arise from decreased holding costs, decreased waste resulting from expired or unsold products, and transportation that is efficient. AI is also a profitability generator through the process of completing orders more accurately, and therefore improving customer satisfaction. Businesses typically see improvements in the accuracy of demand forecasting, increased efficiency, and profitability are the outcome.

Conclusion

The world of inventory management is not the same as it used to be, and it demands more agility, accuracy, and intelligence than before. From our discussion, we have seen that AI is no longer just a luxury but has become a necessity for companies that want to thrive in a complicated market. Emitrr is at the forefront of this revolution by delivering a strong AI platform that is easy to implement and specifically designed for your major inventory issues.

Be the first to lead the AI revolution with Emitrr. Automate your communications, access real-time data, manage your stocks efficiently, and at the same time, free up your team for strategic work. Emitrr goes beyond just managing the inventory; it is also about transforming it into a winning differentiator.

4.9 (400+

reviews)

4.9 (400+

reviews)